Gas Turbine Engine Combustion

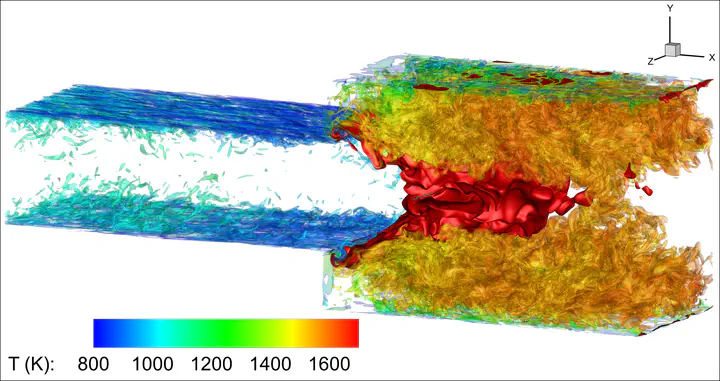

Staged gas turbines with two sequential combustion chambers are being developed for power generation for their ability to achieve low emissions within a wide operational range while conserving high thermal efficiency. A particular implementation of the sequential combustion concept is characterized by a reheat combustion stage downstream of a first premixed-type combustor. Hot exhaust gases from the first stage are mixed with fuel in a mixing section, which provides the inlet conditions for the second-stage reheat combustor. Direct numerical simulations (DNS) of flame stabilization regimes in the reheat burner, i.e. the combustor including the mixing section (duct-in-a-duct), at idealized conditions are performed using a detailed hydrogen-air mechanism. In particular, this project investigates the role of autoignition in flame stabilization under different stratified conditions of fuel-oxidizer mixture at the inlet. Results from the simulations show that the combustion occurs both due to auto-ignition as well as flame propagation. The auto-ignition mode occurs at and around the centerline of the combustor while flame propagation is stabilized at the recirculation zones near the corners. A typical realization of the flow field is shown in the figure. Chemical explosive mode analysis has been employed to quantify the contribution of auto-ignition to the combustion rate relative to flame propagation. The insights from this project are being used by Ansaldo Energia (a major gas turbine company), for the design their next generation gas turbine combustor.